LOTTE INEOS CHEMICAL recognizes health (H), safety (S), and environment (E), which are essential conditions for sustainable businesses, as the top priority of its management activities. In addition, the company has established a safety environment management policy for more solid corporate competitiveness, and all executives and employees, from chief executive officers to employees, are putting the priority on the management.

Safety for us

Environment for the next generation

Health for myself

LOTTE INEOS CHEMICAL is constantly striving to become an advanced business in safety, environment, and health care. In particular, we are fully committed to the basic principles of all tasks under the conviction that 'good safety environment management' is 'a key element of corporate management.'

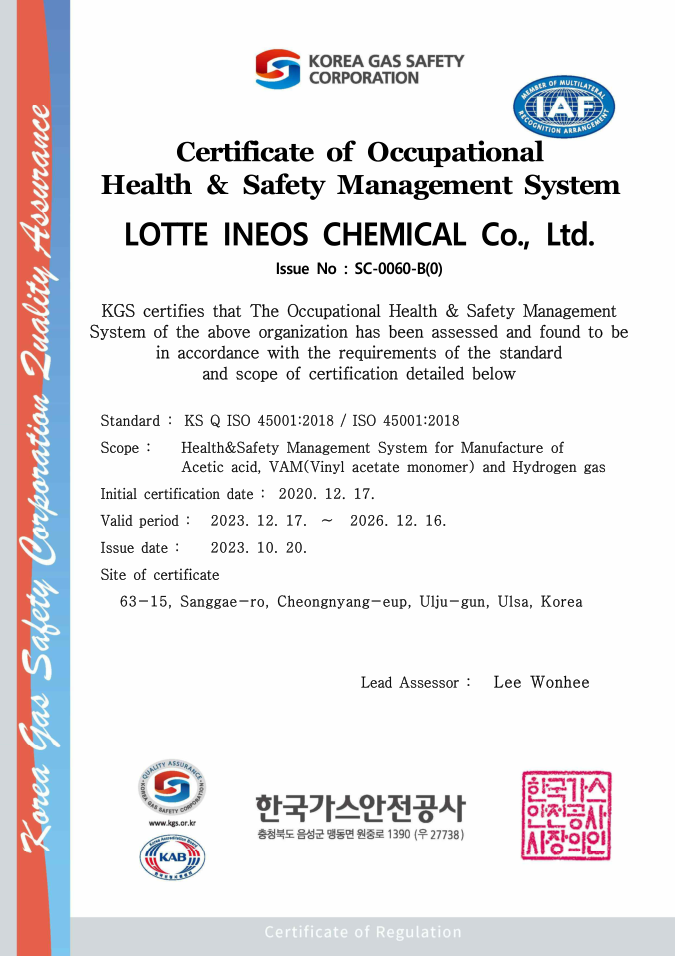

All executives and employees of LOTTE INEOS CHEMICAL are committed to maintaining its disaster-free business through "fair safety, facility safety, and human safety" under the belief that "all disasters can be prevented in. advance"

The disaster prevention center is operated to intensively manage disaster prevention facilities such as automatic fire detection facilities, gas leak monitoring systems, CCTVs, etc. to ensure reliability and to secure a thorough proactive response management system through emergency response training.

Under the goal of "preventing disasters in advance," the company maintains a safe workplace with no safety accidents by conducting various fforts, including training, safety emphasis week, and management of potential problems.

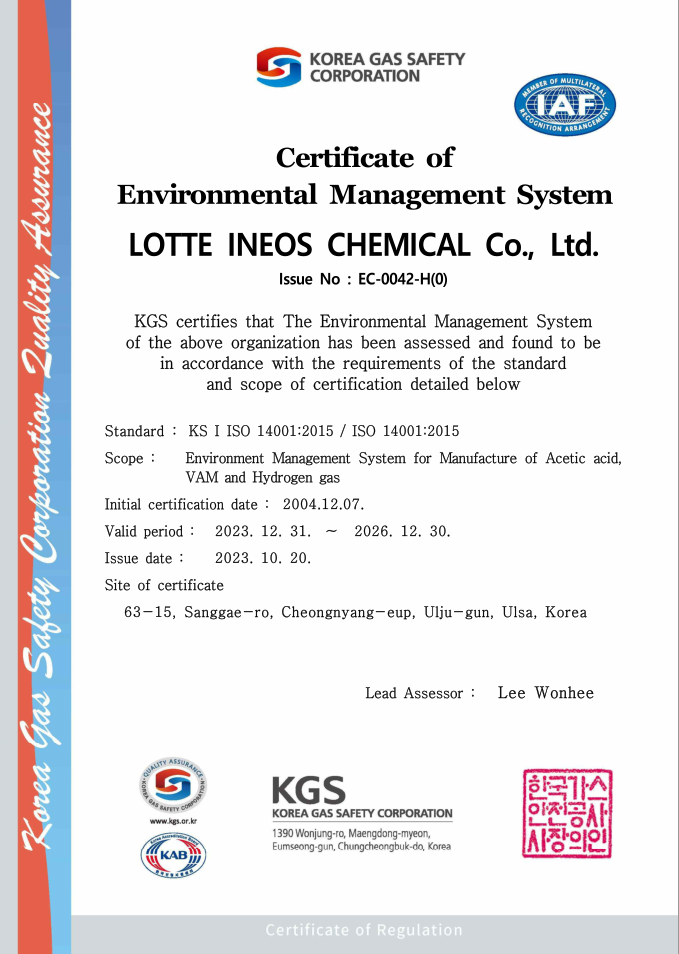

Based on the environmental management system, LOTTE INEOS CHEMICAL focuses on producing environmentally friendly products through efforts to reduce the environmental pollutants and energy as well as complying with domestic environmental regulations.

Various improvement activities are carried out, including the use of clean fuel to reduce air pollutant emissions, reduction of greenhouse gas emissions through energy Retrieval projects and greenhouse gas certification projects, and control of odor and dust emissions through the installation of cleaning facilities.

The amount of wastewater generated by each plant is reduced and decreased, and all generated wastewater is injected into the Yongam public wastewater treatment facility through physical & chemical treatment.

We are making various efforts to minimize waste generated from the production process or during work, and waste generated is recycled as much as possible by classifying it by characteristics or type.

we actively practice health management for employees, creating a pleasant working environment, and health and hygiene management for the implementation of disease-free workplaces and the improvement of individual quality of life.

By creating a pleasant working environment through measurement and improvement activities and operating a health promotion program involving all executives and employees, we are fully committed to managing and implementing disease prevention and disease-free workplaces for our employees.